The natural choice

Produktinformation

Austenitisk stål med betegnelsen 1.4404 indeholder molybdæn ud over krom og nikkel. Bortset fra tilstedeværelsen af molybdæn er forskellen fra 1.4301/1.4307, at nikkelindholdet er større. Denne type af rustfrit stål bliver ofte refereret til som syreresistens, hvilket til en vis grad er en misvisende benævnelse, da materialet kun er resistent mod svage syrer. 1.4404 har et lavt kulstofindhold, hvilket betyder, at det kan blive svejst uden risiko for forringelse af korrosionsresistansen i området af svejsningen. I forhold til styrke er 1.4404 mere eller mindre ækvivalent til de lavere legerede kvaliteter 1.4301/1.4307.

Vinkelstænger i rustfrit stål er produceret ved hjælp af varmvalsning. I vinkelformat af 1.4404 er standardiseret i EN 10088-5. Tibnor’s lagerføring af varmvalsede rustfrie stænger omfatter ligesidet vinkelstænger mellem 25-100 mm og tykkelse i omfanget 3-10 mm.

Tilstedeværelsen af molybdæn sammen med krom gør 1.4404 resistent mod korrosion i svage syrer og vand, der indeholder klorid så længe, at kloridkoncentrationen ikke er for høj. Et eksempel på et miljø hvor stålet er velfungerende, er i saltlastet kystatmosfære.

Formbarheden af varmvalsede vinkelstænger i kvaliteten 1.4404 er fremragende i de fleste koldvalsede arbejdsprocesser, og er ofte bedre end varmvalset ”sort” stål. Materialet er karakteriseret ved en god svejsbarhed, og der forekommer sjældent problemer i fremstillingen af svejste konstruktioner. Bearbejdning kan dog udvise problemer, men kan lettes ved brug af værktøj tilpasset til formålet.

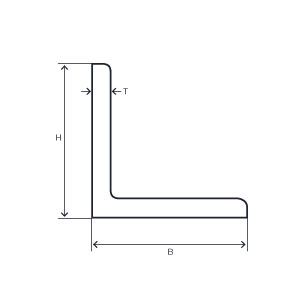

Varmvalset vinkelstål i kvaliteten 1.4404 har overfladebehandlingen 1D som defineret i EN 10088-5 (glødet, bejdset og let eftervalset). Tolerancen for sidelængde og tykkelse er en plus/minus-tolerance som angivet i EN 10056-2. Rethed i form af pilhøjde er maksimalt 0,004 gange stanglængde.