The natural choice

Produktinformation

E355 er analytisk identisk med S355, men betegnelsen "E" indikerer, at det er et rørprodukt. RTU er en engelsk forkortelse for ”klar til brug”, der skal angive, at rørene kan bruges som ydre hylstre til mere basale cylindre i hydrauliske systemer, der arbejder ved relativt lavt tryk. RTU-rørene er fremstillet af plademetal, der formes til et rør ved bøjning og derefter svejses sammen. Efterfølgende koldtrækning af rørene forbedrer styrken og tolerancerne. RTU-rør er forholdsvis tyndvæggede, med en vægtykkelse på max 5 mm.

Svejste, koldtrukne rør i klasse E355 er standardiseret i SS-EN 10305-2. Koldtrækning øger strækstyrken markant fra tæt på 355 MPa i udgangsmaterialet til mere end 590 MPa i de færdige rør. Trækstyrken øges også, men ikke i samme omfang, som strækstyrken og forlængelsen aftager som et resultat af koldtrækning.

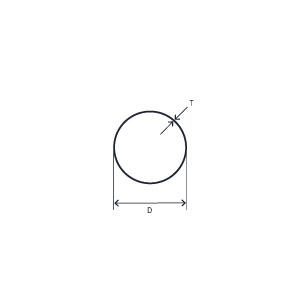

Udvendig diametertolerance for RTU-rør er angivet i SS-EN 10305-2. Indvendig diametertolerance er H9 som defineret i ISO 286-2. Den indvendige overfladefinish i form af Ra er bedre end 0,8 µm. Rethed målt som maksimal pilhøjde er højst 0,001 gange rørlængden.

E355-basisstål i RTU-rør har en fremragende svejsbarhed med en kulstofækvivalent på højest 0,52% med den konsekvens, at forvarmning normalt ikke er nødvendig. Desuden betyder den koldtrukket udførelse, at bearbejdeligheden generelt er ret god.