The natural choice

Produktinformation

C45 er et simpelt konstruktionsstål, der indeholder ca. 0,45% kulstof (C). Det relativt høje kulstofindhold (C) gør stålet egnet til induktionshærdning og sejhærdning (Q + T). Det lave legeringsniveau udelukker imidlertid god reaktion på sejhærdning (Q+T) for større dimensioner.

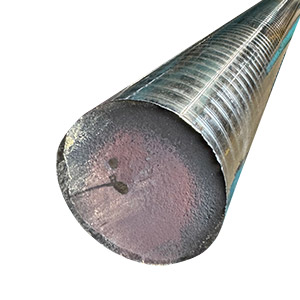

C45E er standardiseret i SS-EN ISO 683 – 1. SS-betegnelsen (udgået) er 1672. Tibnor har valgt at lagerføre stænger af materiale med betegnelse C45R. Den eneste forskel til C45E, er et kontrolleret svovlniveau (S) (min 0,020) for forbedret bearbejdelighed (kort spånet). Diametertolerancen for rundt varmvalset, er som foreskrevet i SS-EN 10060. Rethedstolerance for almindelig rettede stænger er bedre end 0,004 gange stanglængden.

Ved trækprøvning af C45E er det laveste tilladte niveau for flydespænding 310 - 280 MPa afhængigt af diameter. Området for trækstyrke er 590 – 740 MPa og for hårdhed 165 – 220 HB uafhængigt af diameter.

Svejsning af C45E er mulig, men alt andet end meget små dele skal forvarmes. Bearbejdeligheden er meget god, og korte spåner betyder, at materialet er egnet til behandling i ubemandet drift.

Hvis anvendelse kræver det, er C45E særdeles velegnet til induktionshærdning og kan også overfladehærdes ved nitrering. En sejhærdning kan bruges til at øge styrkeniveauet, men hårdbarheden er ikke særlig god, så sejhærdning udføres bedst ved hjælp af vand eller polymer som kølemiddel.