The natural choice

Produktinformation

Austenitisk stål med betegnelsen 1.4301 og 1.4307 er de mest almindelige rustfrie typer, og indeholder 18% krom og 8% nikkel. Forskellen mellem de to dimensioner er, at i 1.4301 er den maksimum tilladte mængde af kulstof højere end ved 1.4307, hvilket betyder, at 1.4301 har en marginal højere styrke. I praksis er forskellen i kulstofindholdet mellem 1.4301 og 1.4307 ofte af mindre betydning. Skal svejsning foretages, er 1.4307 det foretrukne valg, da korrosionsresistansen kan forringes ved området af svejsningen for 1.4301.

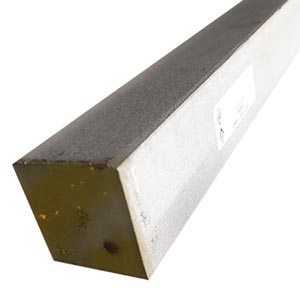

Stangstål af rustfrit stål er produceret ved hjælp af varmvalsning. I firkantet format er kvaliteterne 1.4301/1.4307 standardiseret i EN 10088-3. Tibnor’s lagerføring af varmvalsede rustfrie stangstål omfatter kantlænge i omfanget 12-50 mm.

Kvaliteterne 1.4301 og 1.4307 udviser god resistens mod korrosion i neutralt vand både indendørs og udendørs. Stålet udviser immunitet fra atmosfærisk korrosion. Disse rustfrie ståldimensioner er dog mindre velegnet i miljø, som er syreholdigt, eller indeholder klorid. I disse tilfælde kræves højere legerede dimensioner.

Formbarheden af varmvalset stangstål i kvaliteterne 1.4301 og 1.4307 er fremragende i de fleste koldvalsede arbejdsprocesser, og er ofte bedre end varmvalset ”sort”stål. Begge dimensioner er karakteriseret ved en god svejsbarhed, og der forekommer sjældent problemer i fremstillingen af svejste konstruktioner. Dog kan bearbejdning udvise vanskeligheder, men bearbejdningen kan lettes ved brug af værktøj tilpasset til formålet.

Varmvalsede firkanter i kvaliteterne 1.4301/1.4307 har overfladebehandlingen 1D som defineret i EN 10088-3 (glødet, bejdset og let eftervalset). Tolerancen for kantlængde er en plus/minus tolerance som defineret i EN 10059. Rethed i form af pilhøjde er maksimalt 0,004 gange stanglængde.